We at Arch Plastics Packaging (Arch) set high standards in following & implementing strict cGMP guidelines. Our goal is to meet or exceed the customer requirements and expectations of

our product by actively pursuing quality improvements through programs that enable each employee to perform their job accurately and efficiently the first time and every time.

Our Quality procedures are derived from cGMP principles and are in accordance with the Pharmaceutical Packaging standards, implemented throughout the plant.

Our Comprehensive Drug Master File (#19761, Under Type III Packaging) is active and maintained with FDA. All changes are reported to FDA with amendments to the file.

Strictly compliant to 21CFR210 (Production Goods) and 21CFR211 (Finished Goods).

We comply with all applicable statutory laws and regulations.

We conduct weekly & monthly audits ensuring that there are no deviations from the procedures set forth.

Internal audits are performed annually by cross trained employees and all non-conformities are documented and are addressed immediately.

Our Quality systems are ISO Compliant and strictly follows approved standard procedures for both physical and visual measurements referencing MIL STD 105E (or ANSI/ASQ ZI.4 Table) to ensure the product quality.

We use FDA approved raw materials in our manufacturing process from reliable US-Manufacturing vendors.

FIFO (First-IN-First-OUT) procedures are used for all raw materials and finished products.

Hourly random visual checks are performed by QA on the production lines, ensuring the production quality is as per the requirement.

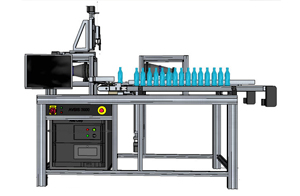

Arch uses state of the art vision based system as well as Calibrated equipment in the lab for measuring all key finished product specifications like thread dimensions, bottle widths, height, min wall thickness, top load, weights, OFC etc...,

Final disposition of the product is the responsibility of QA and proper identification of the finished goods is maintained using Release, Reject or HOLD tickets.

Lot is released and approved for shipment by QA after careful verification of LOT records.

Effective employee training is the cornerstone to our successful operation and customer satisfaction.

New employee orientation as well as the evaluation programs are in place to help employees understand and perform their jobs to the best of their abilities.

Training is an On-Going process and the training programs are properly documented ensuring compliance to standard procedures.

Quality procedures and policies are enforced throughout the plant by maintaining training matrix for all positions in the plant.

Training reviews / assessments are performed annually.

Work Instructions are provided for all critical tasks in the plant and employees are encouraged to participate in their formation and revision.

Employee of the Month, Employee of the Year, Employee birthday celebrations, Best suggestion of the year are some of the encouragements set in the plant.

Traceability is key for both Raw Material as well as Finished Goods. Arch has several checks and balances in place for every key operation for proper traceability.

Certificate of Compliance letter along with necessary raw material COC documentation are part of each shipment.

SPC data analysis is performed for each lot, can be provided to customer upon request.

Use of FDA regulated raw materials with proper documentation can be provided.

Capable of supplying products on Grade A Heat Treated wooden pallets and/or Plastic pallets depending on Customer requirement.

We work closely with our Customers and Suppliers to establish the highest Quality standards.